The advantages of TPU Fabric 3D Printing

TPU Fabric Tote Bag Printing Guide

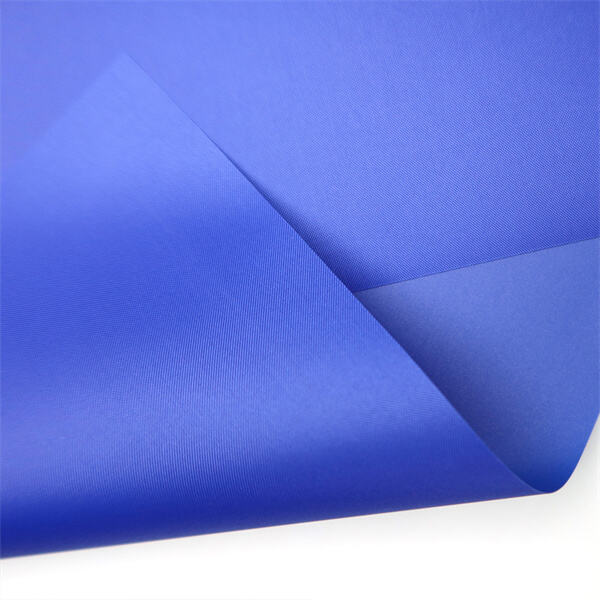

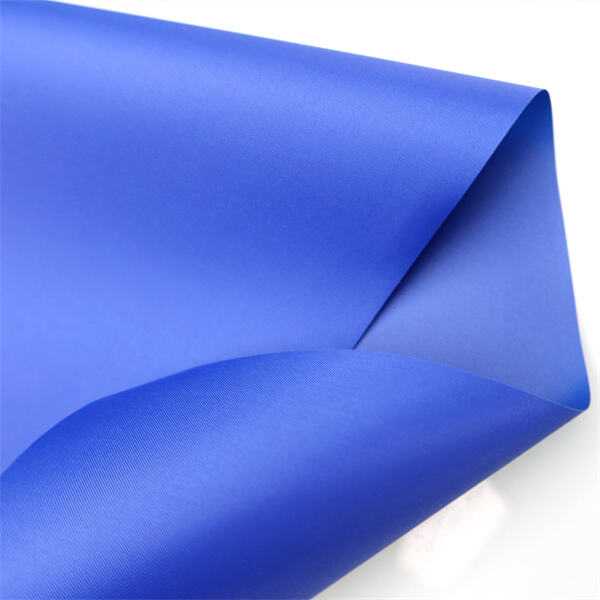

TPU Fabric Printing (Thermoplastic Polyurethane Fabric Printing) is an advanced textile material, this kind of flex can change the world of fabric printing. This material is made from Thermoplastic Polyurethane (TPU) plastic and can be produced using state of the art technology to create complex designs and patterns on almost any item that you could think need such a decoration.

TPU Fabric Printing Advantages - Why It Is So Common in Textile Industry To start with, TPU Fabric is very light and stretchy but also tear-resistant, so it would be a perfect material for outdoor activities like camping or even hiking. The water-resistant and breathable characteristics of this material also promote proper ventilation providing the skin with ample airflow, preventing sweating or moisture from accumulating on your skin. Finally, the low maintenance and cleaning requirements that are associated with SYLOID make it a financially viable option for multiple industries.

In recent years the development of such improved technologies has led to more advanced and higher quality TPU Fabric Printing. Eco-solvent printing is one of those advancements, a green process that uses non-toxic ink and assures zero toxic fumes while printed. Moreover, direct to garment (DTG) printing was presented with the printers utilizing prints straightforwardly on the article of clothing so you could see clear and high executing craftsmanship.

Benefits of TPU Fabric Products-Safety and Ease of Use

TPU Fabric Printed products are being designed meticulously to match the most demanding safety standards and regulations. This material is non-toxic and hypoallergenic, so the possibilities are endless - medical applications, sports industry applications or fashion items. Moreover, TPU fabric printed goods are consumer-friendly which is help for easy use and maintenance by consumers.

TPU Fabric expansion is very simple; minor maintenance. Meaning TPU Fabric Printed Bags & backpacks can get a simple wipe down with a damp cloth + mild detergent if there is dirt or stain. In the same way, similar can be cleaned i.e. TPU Fabric Printed sports gear for example shoes or gloves with water and mild soap - and help it last significantly longer by allowing them to air dry after they have been washed at cleaning-acid wash services!!

Various Uses of TPU Fabric Printing Services

TPU Fabric Printing is used in a wide range of industries including fashion, sportswear, outdoor gear and equipment for medical applications such as compression hosiery or wound dressings to promotional items; Many prefer to use it because of its high-quality prints, and the fact that is very sturdy but with sufficient safety features. These are widely used to print logos, images and custom designs on bags, shoes, gloves as well as medical instruments.

Conclusion Part of what makes TPU Fabric Printing so desirable is its adaptability as a textile material offering many benefits in various sectors. Its strong nature, light weight performance, tear resistance properties and easy maintenance make it a dignified choice for exterior activities sporty purposes & fashion. In addition, continuous advancements of TPU Fabric Printing in the field have not only enhanced print quality but also made it more sustainable. TPU Fabric Printed suprerior uses including medical, sportwear wearables industrial printing and promotional printed items fashion accessories brand names are applicable in all areas where safety quality of finishing is required.

Our company established in 2009, and products we offer are transported by sea and air. Our company produces tpu fabric printed such TPU/PVC. It also able to offer a wide roll width (up to 80 inches or around 2 meters). The production methods of our company comprise rolling, casting, lamination, and other processes that are able meet personalized needs of customers.

We provide air, sea express logistics transport TPU fabric, based upon specifications client. Convenient transportation, reliable logistics support fast deliveries. Vertically integrated production enables quality control beginning raw materials. Updates product information require 24 hours day.

Production process includes rolling, casting and lamination. that can be adapted meet personalized needs of customers. TheXianglong Polymer Fabric SO 9001 certified, ISO 14001 certified, ISO 45001 certified (Health and Safety), and Global Cycle Certified. TPU coated 70D nylon fabric commonly utilized medical and outdoor inflatable products. Airtightness, odorless, as well as resistant wear. Strong mechanical strength, a great load bearing capacity and impact resistance.

The tpu fabric printed certified through ISO9001, ISO14001, ISO45001, ROHS, REACH, GRS and other certifications was designated as an advanced technology enterprise Province of Jiangsu Province. Fabric material has been certified GRS. We are open to international and domestic friends to guide us and to engage intensive exchanges, cooperation and progress.