Laminated Nylon: A Fabric Of Its Own That Revolutionized Clothing

Known for Laminate nylon fabric that is an entirely new thing in the world of wear. Due to a number of benefits, this new material is currently among the best choices for many applications. So, now we will go deep into the awesome features and uses of laminated nylon fabric.

Mixture of nylon fabric is a game changer in the sense that it possesses so many structural positives over regular fabrics, It could almost be argued as better than most. Noteworthy is that it consists of waterproof, windproof as well as breathable features to offer protection from harsh climate conditions while ventilating properly. This amazing feature also makes it great for outdoor use; camping, hiking and skiing. And as its light and compact, it is convenient to carry with you anywhere since it folds quickly saving on storage space.

What Makes Laminated Nylon Fabric So Great?

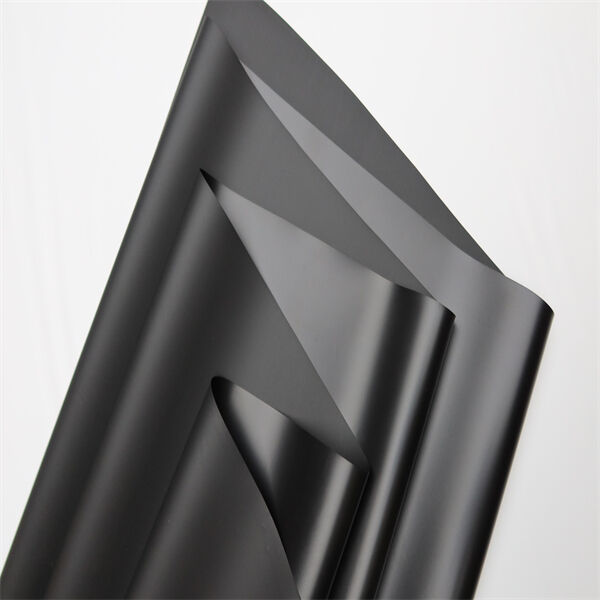

Laminated nylon fabric is created by an innovative process in which layers of nylon are hot pressed and bonded together. When Gore-Tex or other waterproofing application is added in-between a layer of nylon, the result is a highly durable fabric that provides excellent windproof and waterproof characteristics whilst still being breathable.

One of the major benefits with laminated nylon fabric would be its safety as it is very resistant to abrasions, which means a lower chance for ripping or tearing compared to traditional fabrics. Its durability makes it good for protective gear like helmet, gloves and jackets. Also, its top-grade UV protection features work as a barrier for hazardous sun rays reducing the risks of one's skin from skin issues and health problems.

Laminates are widely used across various industries from nylon fabrics. Used in the apparel industry, it is made into jackets, pants and gloves to name a few. It is used in the medical industry especially to produce, protective covers for various devices as well as surgical gowns and other equipment that require water repellency and wind protection. Moreover, this is also used in the construction industry for manufacturing tents, tarpaulins and protective coverings etc.

Straightforward Directions for Making Use of Laminated Nylon Fabric

Laminated nylon fabric is easy to use. Decide on the clothes or kits you want to make, buy fabric from some place reputable - online if need be with samples and at your local house of fabrics. Once you have the fabric, start crafting by cutting it to size. After which, the edges should be folded together and sown giving room for other extras such as zippers, buttons or handles to adorn and solidify its use plus beauty.

Laminated nylon fabric offers one key benefit- durability and long life. Available in an extensive range of colors, this sturdy material is worth every cent for weatherproof and hard wearing items. In addition, it is easy to care for as you can wash this by hand or in a washing machine and still be assured of its durability.

Our company established in 2009 and we mainly ship products by ocean and air. Our group has capacity of creating laminated nylon fabric, like TPU/PVC, with benefit of having a wide roll width (up to 80 inches, which about 2 meters). The processes used by company for production include rolling, casting lamination, and more which are able to satisfy specific requirements of customers.

Convenient transportation, reliable logistics support fast deliveries. Integrated production allows laminated nylon fabric quality control raw materials. Receive information about product updates you require 24 hours day. We provide sea, air and express logistics transport TPU fabric, depending needs our customers.

Lamination, rolling, casting as well as other production methods are readily available meet customers' needs. The Xianglong Polymer Fabric has been awarded ISO 9001, ISO 14001 as well as ISO 45001 (Health and Safety) certifications. Additionally, it also acquirable Global Cycle certification. TPU-coated 70D nylon fabric commonly utilized medical and outdoor inflatable products. No odor, excellent wear resistance, and high airtightness. Good mechanical strength and great load bearing capacity and impact resistance.

It was recognized as an advanced technology enterprise within Jiangsu Province. laminated nylon fabric material certified GRS. We welcome domestic and international partners to guide us and to engage intensive exchanges as well as cooperation and advancement.