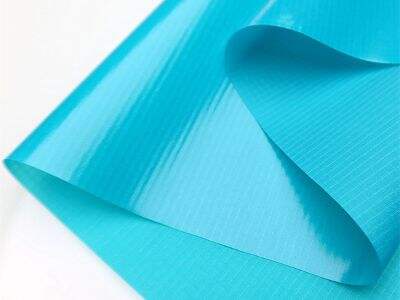

When you are involved in work projects require materials to be durable and strong, you may have heard about Ripstop nylon fabric 6 and Nylon 66. It’s essential to understand the distinctions between them to select the appropriate one for your project. This guide from Xianglong Polymer Fabric provides an overview of everything you should know about Nylon 6 and Nylon 66.

Comparison Between Nylon 6 and Nylon 66.

Both Nylon 6 se Nylon 66 are synthetic materials, however they are made differently. Nylon 6 uses one type of building block, or monomer, while Nylon 66 uses two different monomers. This variation results in some unique characteristics for Nylon 66, making it a preferred material for applications requiring additional strength and durability.

Which Should You Use, Nylon 6 or Nylon 66?

Some considerations for using either Nylon 6 or Nylon 66 in your projects Unlike Nylon 66, Nylon 6 is more flexible and has a lower melting point. This means that Nylon 6 is an ideal material for projects that require bending and stretching. Nylon 66, on the other hand, copes with higher temperatures and has greater resistance to heat and chemicals, making it the better choice for hard projects.

Pros and Cons of Nylon 6 and Nylon 66

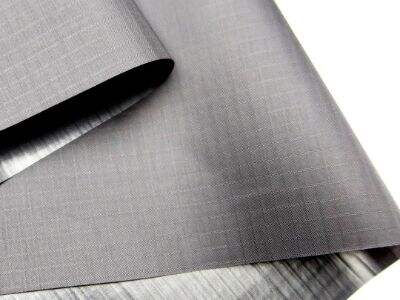

Nylon 6 is a handy material that requires no special equipment and is a great fit for many projects where wear resistance is a necessity. On the other hand, the fact that it melts at a lower temperature and is more flexible means that it may not be ideal for designs that need to be resistant to high heat and be rigid. Ripstop nylon 66 has better heat resistance and stiffness, which makes it a good choice for applications that will experience harsher environments.

Picking the Right Options for Your Projects

Consider what your project requires when deciding between Nylon 6 and Nylon 66. Nylon 6 may be the better polymer if you want something that can bend and stretch without breaking. However, if you require something that can withstand extremely high temperatures and aggressive chemicals, Nylon 66 should be used instead. By knowing what these materials are and how they differ, you can choose the right one for your project.

Why Choose Nylon 66 for Your Project?

Nylon 66 is a better choice for projects that require extra strength and durability. It has better temperature tolerance and is more chemical resistant, making it an excellent fit for use cases where Nylon 6 may not perform as effectively. In addition, Nylon 66 has improved, the stiffness, a better rigidity at retained shape which is suitable for projects requiring a solid material.

That said, if you're trying to decide between Nylon rip stop 6 and Nylon 66 for your projects, consider what you're asking for. Nylon 6 is flexible and useful, but Nylon 66 is stronger, damage-resistant, and heat-resistant. Understanding the differences of these two materials will allow you to choose the best option for your projects. This is why Xianglong polymer fabric materials have many nylon materials suitable for your projects.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

BN

BN